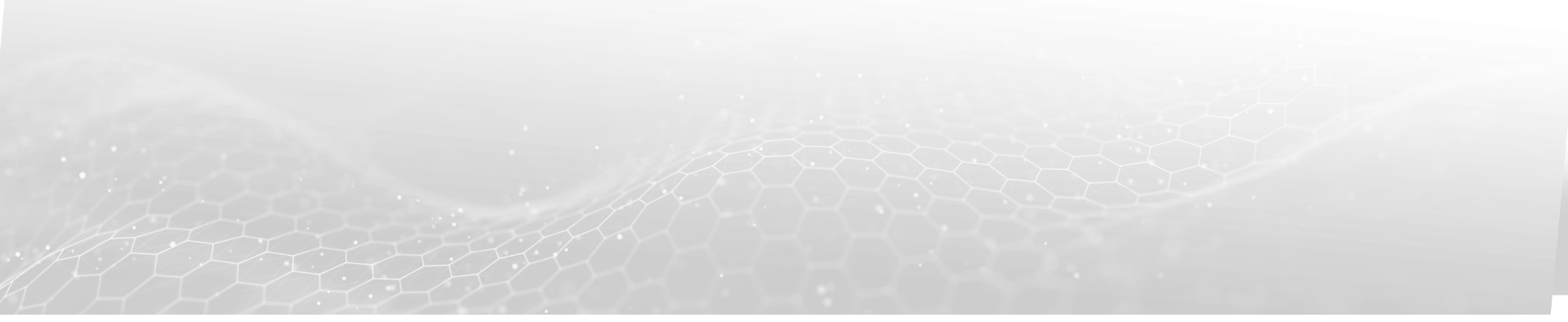

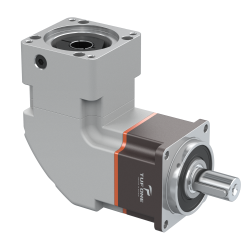

TUF

- Ratio : 3~100

- Flange Size mm : (mm) 42, 60, 75, 100, 140, 180, 220

- Standard Backlash arcmin : ≤ 6

- Reduced Backlash arcmin : ≤ 1~ ≤ 2

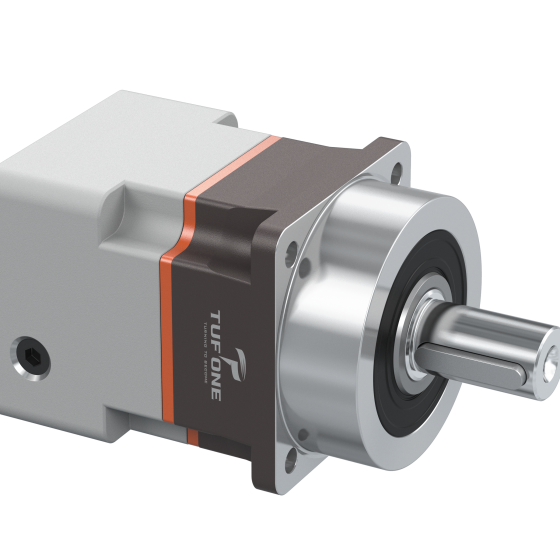

TUF is designed with Taper roller bearings to handle greater axial and radial forces.

Minimizing loss、Advance、Smooth.

With high precision positioning, TUF is specifically designed for equipment requiring repetitive positioning, and widely used in applications such as machining machinery and semiconductor production lines. The output shaft can be selected with a key according to requirements, making it versatile and flexible for using in various mechanical and equipment setups. TUF is designed to align with market standard specifications, which eliminatis compatibility concerns.

TUF's helical gear design greatly enhances the durability and efficiency of gear operation. This is achieved through our advanced gear processing technology and unique tooth surface heat treatment, significantly improving gear wear resistance and smooth meshing.

TUF offers a wide range of ratios from 3 to 100, meeting nearly 99% of deceleration requirements for equipment. Its maximum output torque reaches up to 1,500Nm, easily handling applications with heavy load demands, helping you achieve high efficiency, high precision, and stable mechanical operation. One stage models (reduction ratios 3–10) achieves up to 97% efficiency, while two stage models (reduction ratios 12–100) achieves up to 94% efficiency.

* International Protection Marking, IEC 60529. IP65